What is Last Mile Sorting and Distribution Center

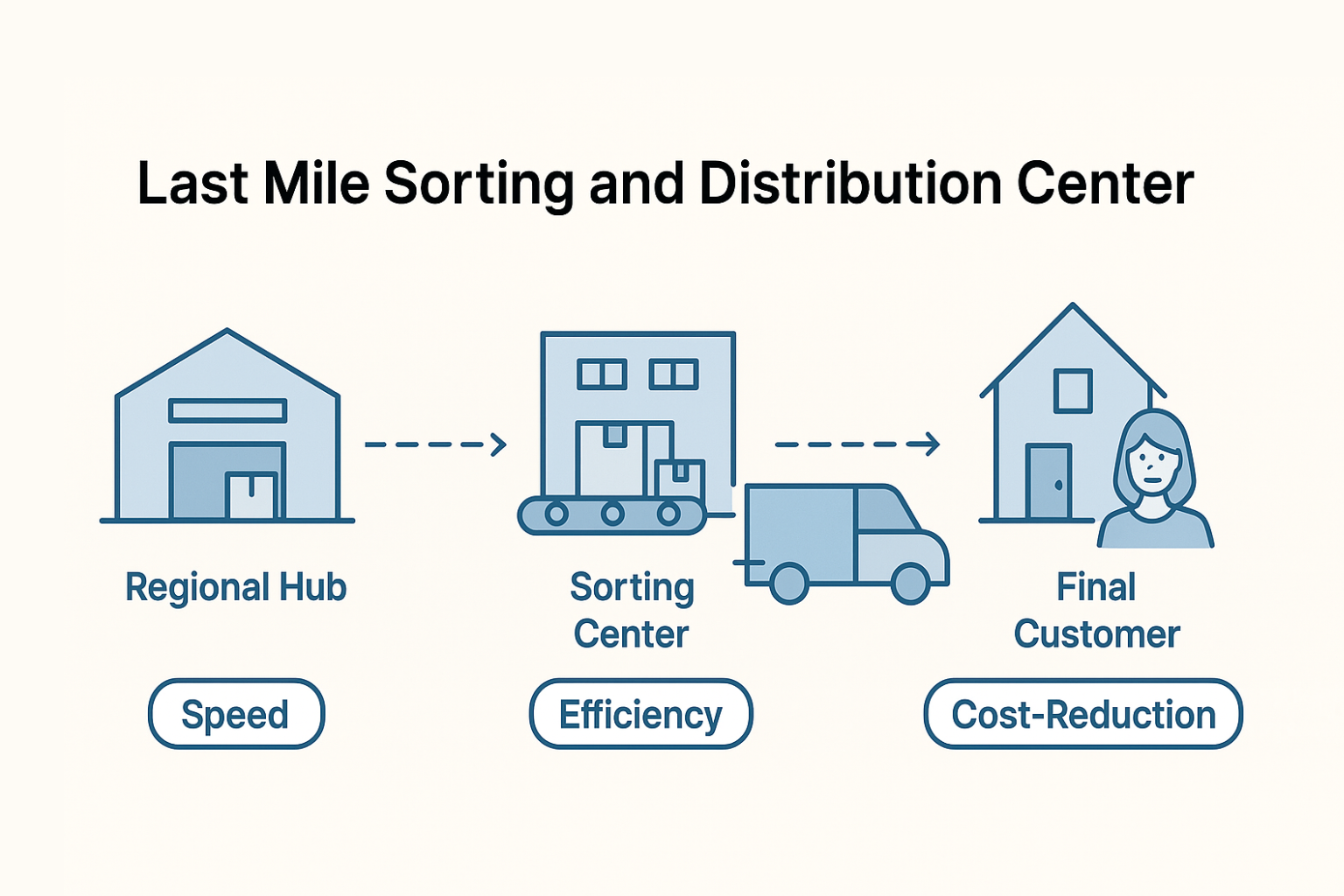

Last mile logistics is the final stage of the delivery process, where products move from a distribution hub to the customer’s doorstep. This critical phase has become more complex and important in today’s e-commerce world, where consumers expect fast, efficient and cost-effective deliveries.

At the heart of successful last mile operations are sorting and distribution centers, which are the vital nodes in the supply chain network. These facilities are the centralized hubs where incoming shipments from various sources are received, sorted and reorganized for local delivery.

By using advanced technologies like automated sorting systems, real-time tracking and route optimization software, these centers enable companies to streamline operations, reduce transit times and minimize costs.

Moreover, strategically located sorting and distribution centers allow businesses to be closer to end customers and respond faster to fluctuating demand. As e-commerce grows and consumer expectations evolve, the role of these centers in orchestrating seamless last mile logistics will only become more important in the supply chain.

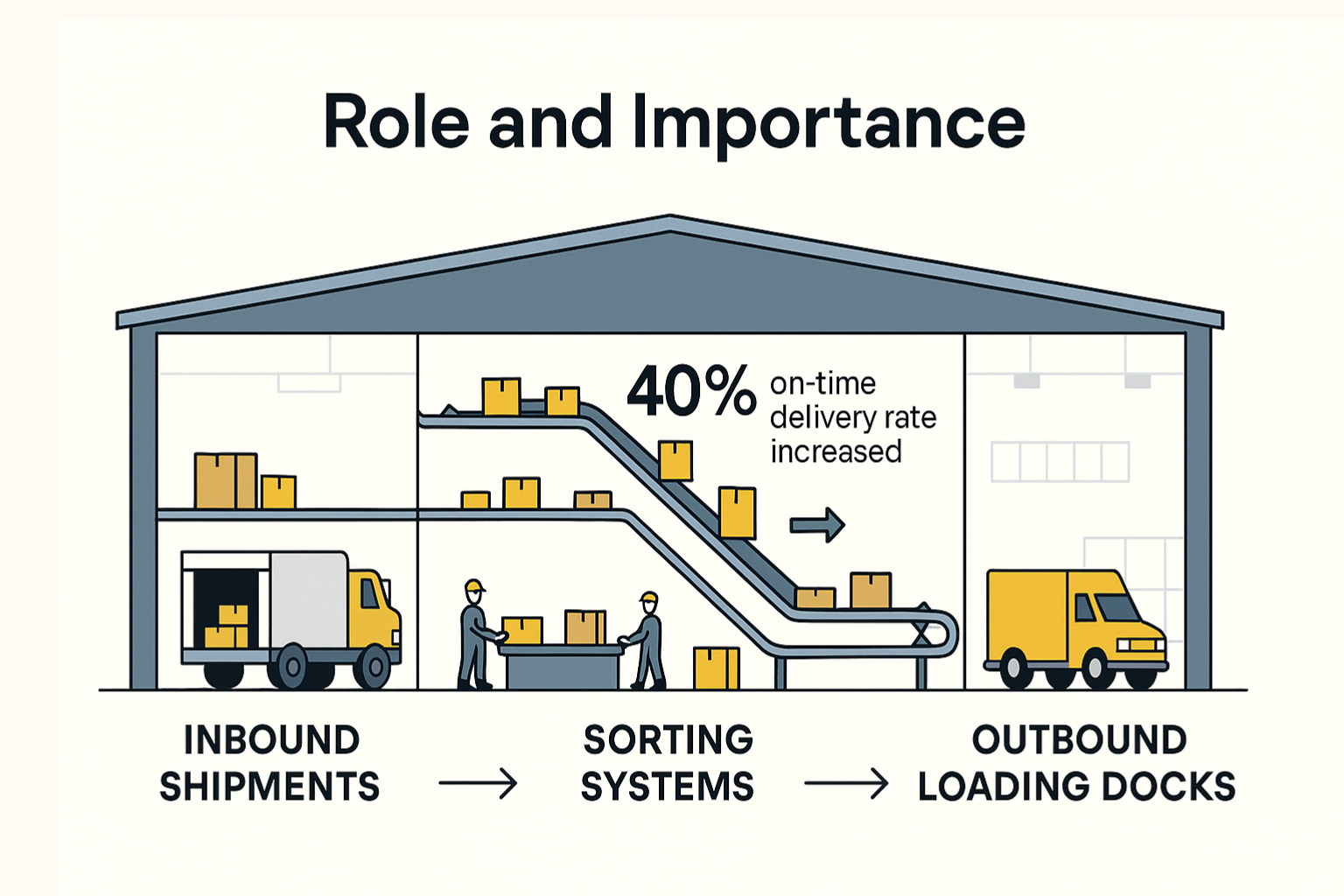

Role and Importance

Last mile sorting and distribution centers are the final link between retailers and consumers. These facilities are the hubs where incoming shipments from various sources are consolidated, sorted and prepared for final delivery to customers. Operating with a combination of technology and skilled personnel, these centers process large volumes of packages, organizing them by destination and delivery route. Automated sorting systems, conveyor belts and barcode scanners work together to streamline operations and minimize errors.

Once sorted, packages are loaded onto delivery vehicles for the final leg of their journey. These centers also handle returns and are a temporary storage for items awaiting pickup or redelivery. By optimizing the last mile delivery process, these facilities reduce costs, improve delivery times and overall customer satisfaction in an increasingly competitive e-commerce landscape.

According to Wise Systems, Last mile delivery accounts for approximately 53% of total shipping costs, highlighting the critical role of sorting and distribution centers in cost management. Efficient operations in these centers are essential to reducing this significant expense while meeting consumer expectations for rapid delivery.

Efficiency in Operations

To optimize sorting and distribution processes, businesses must adopt a multi-faceted approach that combines technology with workflow. Implementing advanced automation systems like AI-powered sorting machines and robotic picking arms can reduce human error and increase processing speed.

Data-driven decision-making through real-time analytics and predictive modelling can help with demand forecasting and inventory management. Lean methodologies like Just-in-Time (JIT) inventory and continuous improvement can eliminate waste and bottlenecks in the supply chain.

Investing in employee training and cross-functional collaboration ensures staff are equipped to handle complex sorting tasks and adapt to new technology. By using these strategies, businesses can improve operational efficiency, reduce costs and deliver better service to their customers in a competitive market.

Order Fulfillment

Last mile centers have transformed the e-commerce landscape by speeding up order fulfillment and delivery. These strategically located distribution hubs bring inventory closer to end consumers, allowing retailers to reduce shipping times and meet the growing demand for same-day or next-day delivery.

By decentralizing inventory and optimizing local routes last mile centers enable faster order processing and more efficient dispatching of delivery vehicles. This streamlined approach not only improves customer satisfaction but also reduces transportation costs and minimizes the environmental impact of long-distance shipping.

Last mile centers also provide more flexibility in handling returns and exchanges, further improving the customer experience. Businesses that use these facilities gain a competitive advantage in the market, meeting customer expectations for fast delivery while improving operational efficiency and bottom line.

Key Components

Transportation and Delivery Vehicles

Transportation and delivery vehicles are the last mile of logistics, the final link between distribution centers and end customers. These vehicles, from traditional vans and trucks to electric bicycles and drones, are essential for the efficient and timely delivery of goods in urban and suburban areas. The choice of vehicle depends on package size, delivery distance and local regulations.

In recent years, there has been a growing emphasis on sustainable and eco-friendly options, with many companies adopting electric and hybrid vehicles to reduce their carbon footprint. The rise of e-commerce and same-day delivery has led to increased demand for versatile and agile delivery vehicles that can navigate city streets and reach customers quickly. As last mile logistics evolves, the importance of choosing the right transportation and delivery vehicles becomes even more critical for businesses looking to optimize their supply chain and meet customer expectations.

Warehouse and Inventory Management

Warehouse management software has changed the way businesses manage their inventory, a powerful tool for inventory management. This technology streamlines operations by providing real-time visibility into stock levels, order fulfillment and warehouse activities. By automating processes like receiving, put-away, picking and shipping, warehouse management software reduces human error and improves overall accuracy. It also enables better space utilization through intelligent storage strategies and optimized picking routes.

Many of these systems also include features like barcode scanning, RFID tracking and mobile device compatibility to enhance data collection and accessibility. The result is a more agile and responsive supply chain that can adapt to fluctuating demand and minimize stockouts or overstocking. By using warehouse management software, businesses can improve operational efficiency, reduce costs, increase customer satisfaction and get a competitive edge in today’s fast-paced business world.

Parcel Volume and Sorting

As e-commerce grows and customer expectations for fast delivery increase, logistics companies are faced with the challenge of handling more parcel volumes while being efficient. To address this, businesses are turning to advanced sorting technologies and process optimization.

Automated sorting systems powered by AI and machine learning can increase throughput and accuracy, reduce manual labour and errors. Cross-belt sorters, tilt-tray sorters and dimensioning systems can streamline operations and space utilization.

Data analytics also plays a key role in predicting volume fluctuations and workforce allocation. By embracing these innovations and continuously refining processes, businesses can manage more parcel volumes, reduce bottlenecks and meet the demands of today’s fast-paced delivery landscape while keeping costs under control.

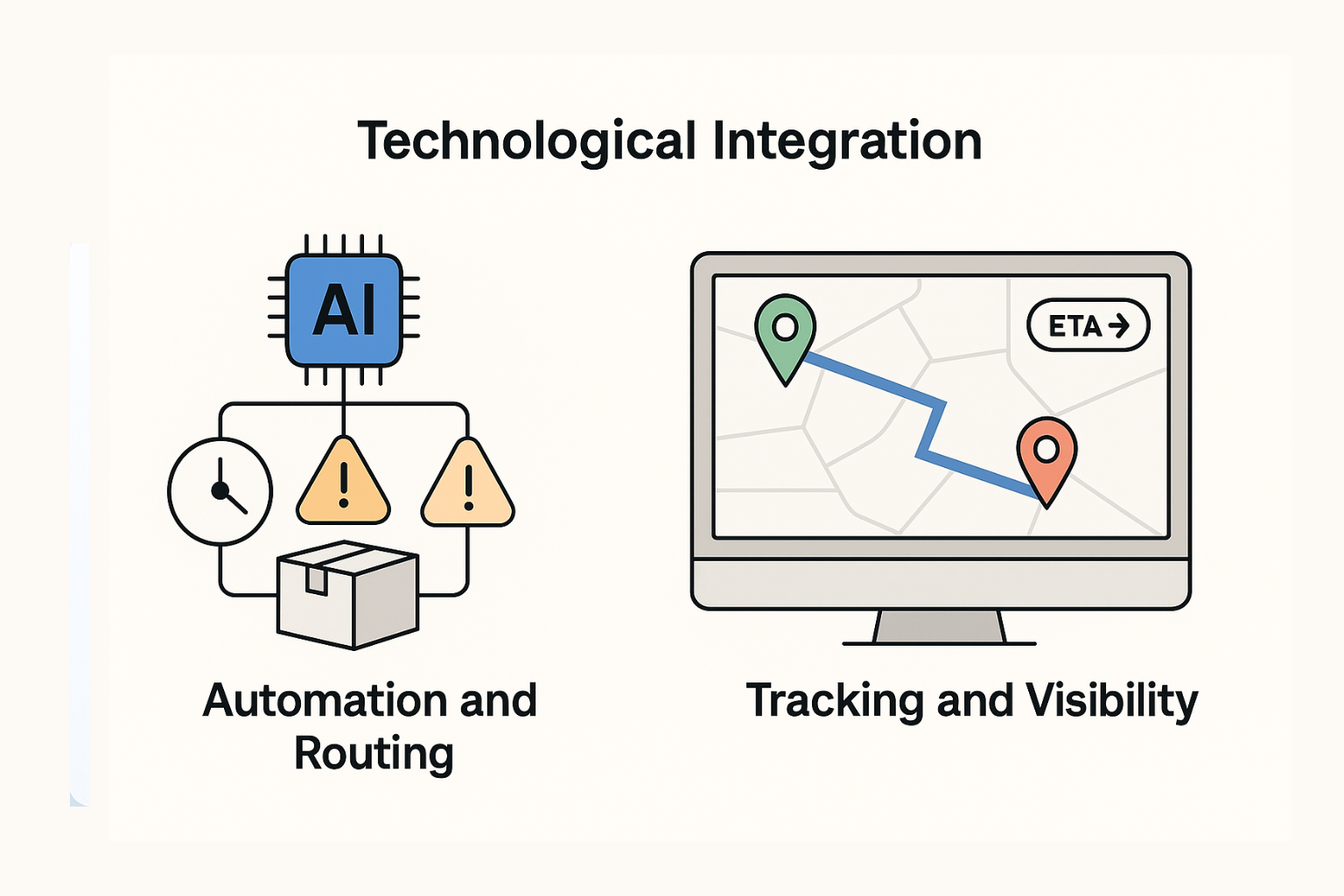

Technological Integration

Automation and Routing

In today’s fast-paced business world, companies are turning to automation and route optimization to get ahead. By using advanced software, businesses can automate repetitive tasks, reduce human error and improve efficiency across departments. Route optimization algorithms have changed logistics and delivery services by calculating the most efficient routes for vehicles, taking into account traffic patterns, delivery windows and vehicle capacity.

This reduces fuel consumption and transportation costs and improves customer satisfaction through on-time delivery. The integration of AI and machine learning into these systems allows for continuous improvement and adaptation to changing conditions. Businesses that adopt automation and route optimization are better equipped to meet their customers’ increasing demands while reducing operational costs and environmental impact.

Tracking and Visibility Solutions

In today’s fast-paced and connected global market, distribution center tracking and supply chain visibility solutions are the key to winning. These advanced technologies provide real-time visibility into stock levels, shipment status and overall supply chain performance so businesses can make data-driven decisions and respond to market demands. By using robust tracking systems and visibility solutions, businesses can optimize their operations, reduce costs and improve customer satisfaction.

These tools help identify bottlenecks, streamline processes and improve collaboration between suppliers, manufacturers and retailers. With visibility across the supply chain, businesses can mitigate risks, anticipate disruptions and take proactive measures to ensure business continuity. As customer expectations for faster delivery and transparent order tracking continue to rise, investing in distribution center tracking and supply chain visibility solutions is no longer a competitive advantage but a necessity to survive in today’s business world.

Challenges and Solutions

Delivery Challenges

Last mile delivery, the final step in the supply chain process, is a big problem for logistics companies and retailers. One of the biggest challenges is the cost of individual deliveries to multiple locations. Traffic in urban areas means delays and inefficiencies, while rural deliveries are time-consuming and expensive due to distance. Failed deliveries and returns are also a major challenge, increasing operational costs and customer dissatisfaction.

To address these issues, companies are looking at innovative solutions like automated lockers, drone deliveries and crowdsourced delivery networks. Route optimization software and real-time tracking systems are being implemented to improve efficiency and reduce fuel consumption. Many businesses are also adopting sustainable practices like electric vehicles and bicycle couriers to reduce their environmental impact. By using technology and thinking outside the box, companies can overcome last mile delivery challenges and provide a seamless experience for their customers while staying profitable.

Cost Management

Delivery costs are key to businesses staying profitable in today’s competitive world. One way to do this is to optimize route planning using advanced software to determine the most efficient routes for drivers, reduce fuel consumption and time on the road. A dynamic pricing model that adjusts delivery fees based on distance, time of day, and order volume can help offset costs during peak periods. Partnering with local couriers or setting up a network of micro-fulfillment centers can reduce last mile delivery costs.

Offering incentives for customers to choose pickup options or consolidated delivery days can streamline operations. Investing in eco-friendly vehicles and exploring innovative solutions like drone or autonomous vehicle deliveries can lead to long-term cost savings. Finally, regularly reviewing delivery data and customer feedback can help identify areas for improvement and cost reduction so your delivery operations remain lean and efficient.

Impact on E-commerce

Last mile sorting and distribution centers are key to supporting e-commerce growth by streamlining the final stages of order fulfillment. These strategically located facilities act as hubs where incoming shipments are quickly sorted, organized and dispatched to their final destinations.

By siting these centers closer to urban areas and high-density population centers, ecommerce companies can reduce delivery times and transportation costs. This proximity enables more efficient route planning and same-day or next-day delivery options, which are becoming increasingly important to customers. These centers often incorporate advanced technologies like automated sorting systems, robotics and AI-driven inventory management to speed up and improve the fulfillment process. As e-commerce grows, last mile sorting and distribution centers will be essential to meeting the growing demand for fast and reliable delivery while helping businesses stay competitive in the digital market.

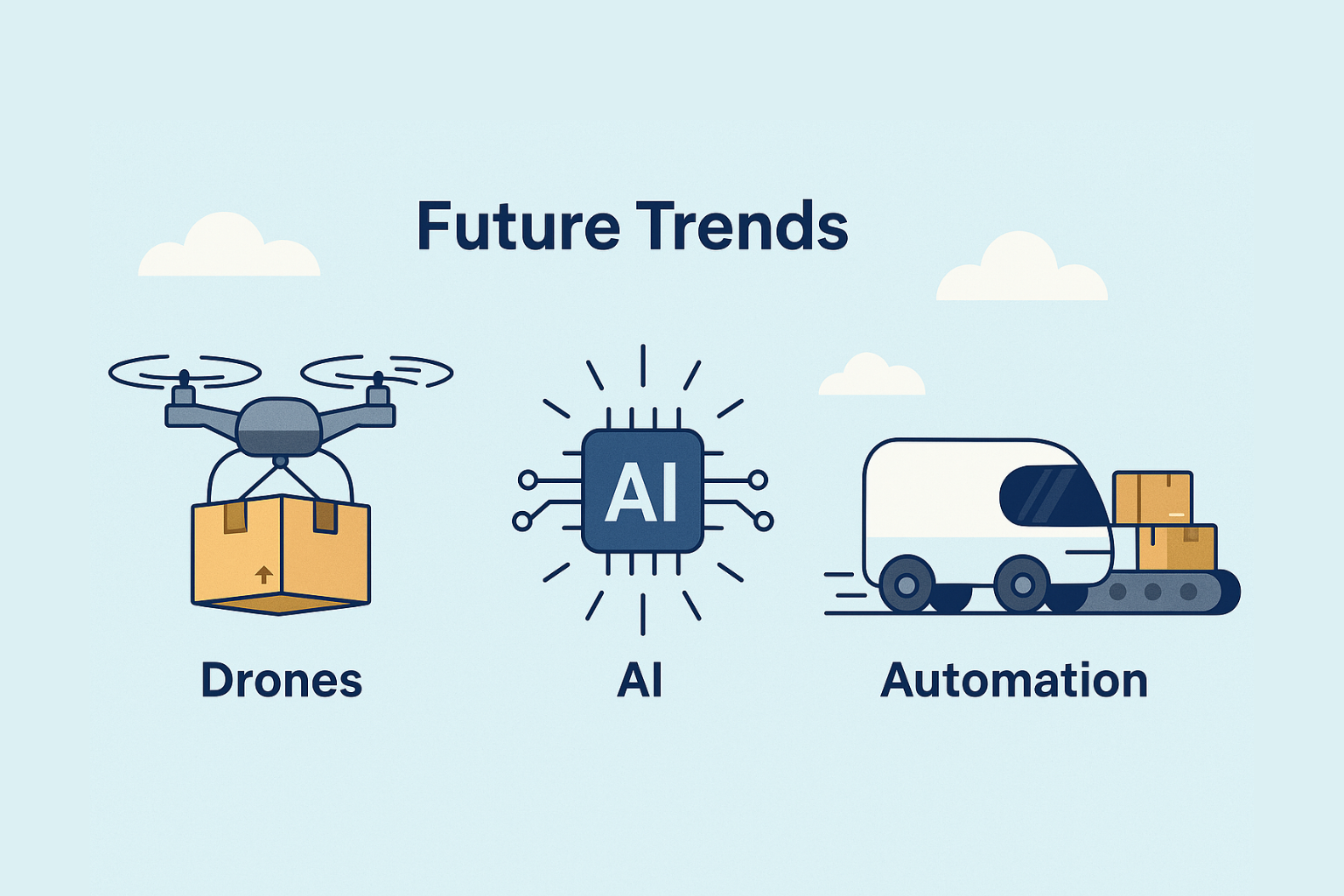

Future Trends

Last mile sorting and distribution centers are evolving as e-commerce grows and customer expectations for faster delivery increase. Several trends and innovations are shaping these facilities. Automation is leading the way with advanced robotics and AI-powered systems, sorting and speeding up the process. Micro-fulfillment centers are becoming popular, bringing inventory closer to urban consumers for faster delivery. IoT devices and real-time data analytics are enabling more accurate inventory management and route optimization.

Sustainable practices are also on the rise, with companies introducing eco-friendly packaging and electric delivery vehicles. Drones and autonomous vehicles for last mile delivery are being tested in some markets. These innovations are not only improving operational efficiency but also the overall customer experience in the e-commerce logistics game.

According to MDPI’s 2024 review, “Drones are utilized for rapid deliveries, but their low payload capacity and high cost of purchase render them less suitable for high-volume logistics.” This highlights the potential of drones for niche last-mile applications while acknowledging challenges in scaling.

Conclusion

Last mile sorting and distribution centers are the final piece of the puzzle, the link between retailers and consumers. They are located near urban areas to speed up the delivery process and reduce transit times. Their role is to sort, organize and dispatch packages for final delivery, often same day or next day. By optimizing routes and consolidating shipments, these centers reduce costs and environmental impact.

They also enable companies to meet the growing customer demand for faster and more flexible delivery options, which is now a key differentiator in the e-commerce world. As e-commerce grows, the importance of last mile sorting and distribution centers in delivering seamless, cost-effective and on-time delivery cannot be ignored; they are the heart of modern supply chain management.