- Written by:

- Amanda Conway

- Last Updated: November 14, 2025

Your warehouse is growing, but your systems aren’t keeping up. Inventory counts don’t match what’s actually on the shelves, orders go out late or wrong, and you’re burning cash on labor just to keep things moving. You know there’s a better way, but figuring out what a warehouse management system actually does-and whether it’s worth the investment-feels like another project you don’t have time for.

A warehouse management system (WMS) isn’t just software that tracks boxes. It’s the operational backbone that tells you where everything is, how to pick it faster, and what’s actually happening in real time. The right WMS software can cut picking errors, speed up fulfillment, and give you the visibility you’ve been faking with spreadsheets.

This guide breaks down what warehouse management systems actually do, which features matter for 3PL warehouse management and growing operations, and how to choose one that scales with you.

Table of Contents

TL;DR

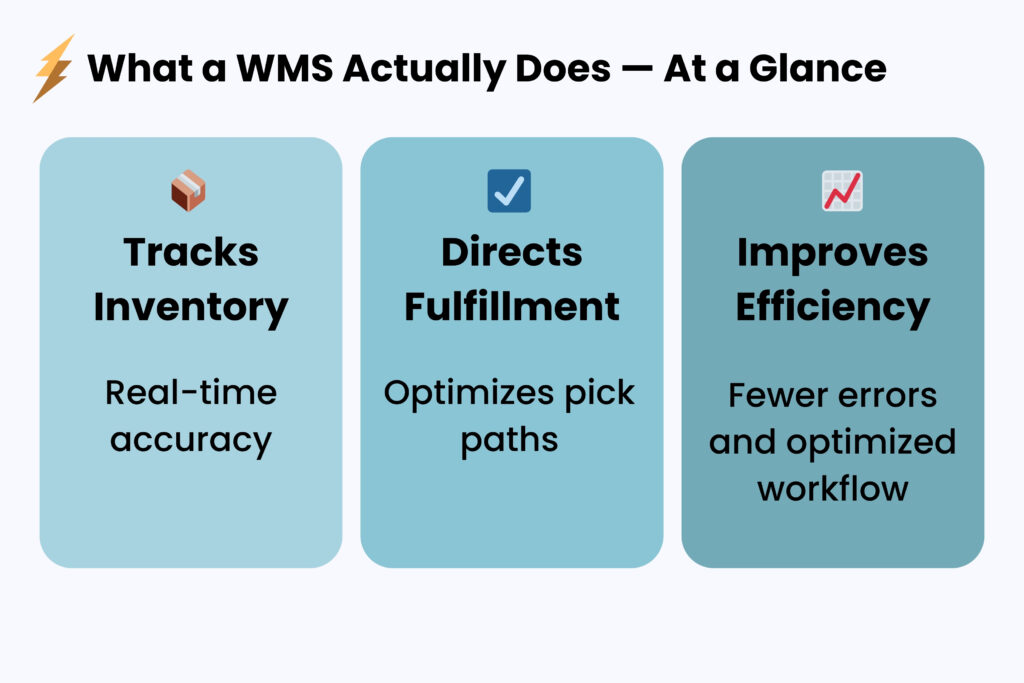

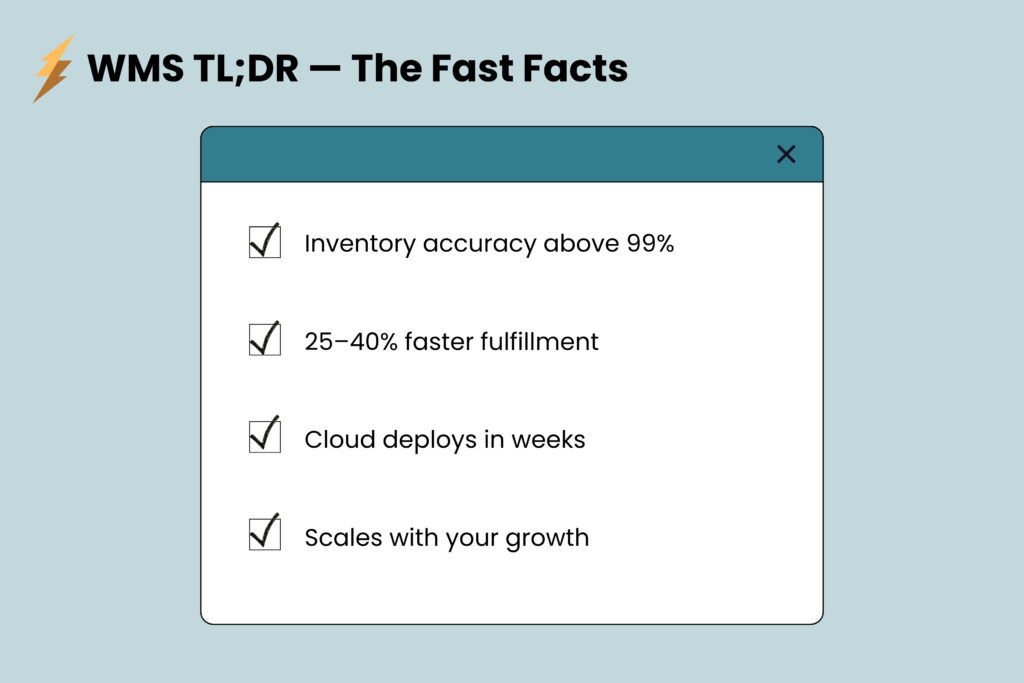

- WMS software orchestrates warehouse operations by tracking inventory, directing workers, and optimizing pick paths in real time.

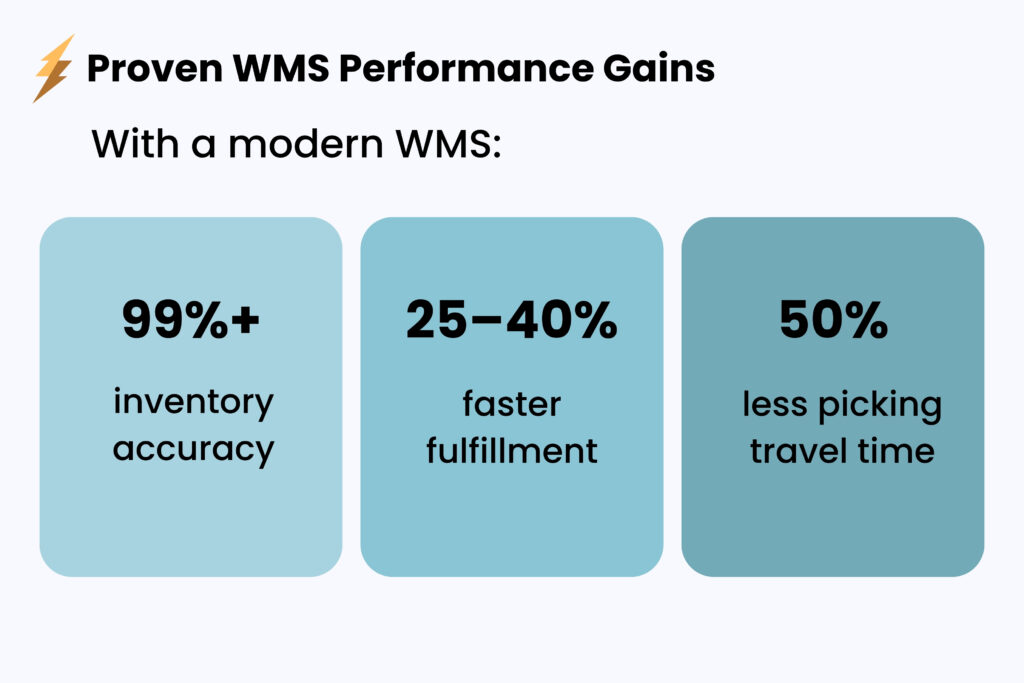

- Modern systems push inventory accuracy above 99% and increase fulfillment speed by 25-40% through directed workflows.

- Cloud WMS deploys in weeks versus months and scales without infrastructure investments or custom workarounds.

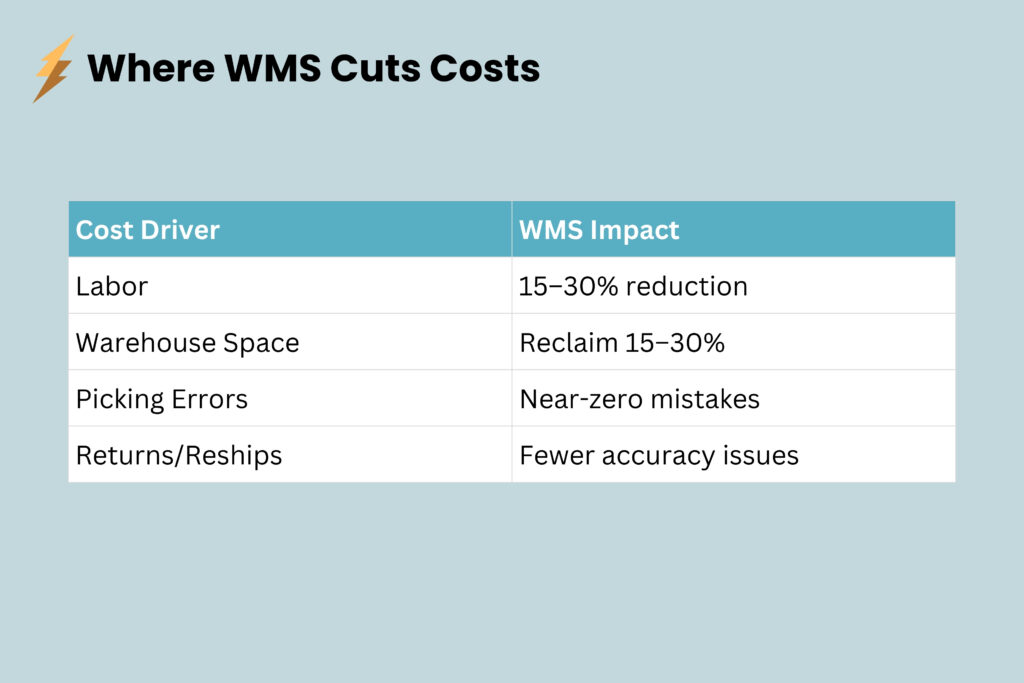

- The right system cuts labor costs 15-30% and reclaims warehouse space through optimized slotting strategies.

- Choose based on your actual operations and three-year growth plan, not the longest feature list.

You’ve probably heard the term thrown around in meetings, but let’s cut through the noise and talk about what a warehouse management system actually does for your operation.

What Is a Warehouse Management System?

The Core Definition

A warehouse management system is software that orchestrates everything happening inside your four walls. It tracks inventory from the moment it arrives until it ships out, directing where products go, how they’re picked, and the most efficient path to get them packed and on a truck. Think of it as the brain that tells your warehouse workers what to do, when to do it, and where to do it-eliminating the guesswork that slows operations down.

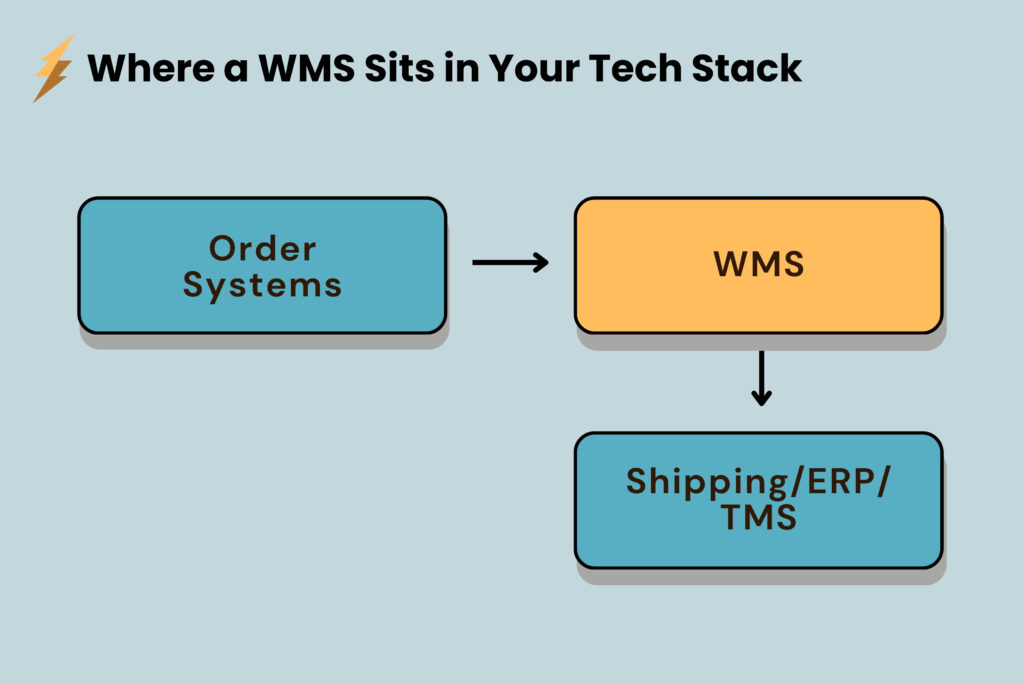

How WMS Fits in Your Technology Stack

Your WMS doesn’t work alone. It sits between your customer-facing systems (like your e-commerce platform or order management system) and your warehouse floor. When an order comes in, your WMS receives it, figures out the optimal pick path, assigns tasks to workers, and confirms shipment back to your order system. Modern cloud warehouse management systems integrate with transportation management systems, ERPs, and shipping carriers to create a connected supply chain. This isn’t just about tracking boxes-it’s about making sure every system talks to each other without manual data entry.

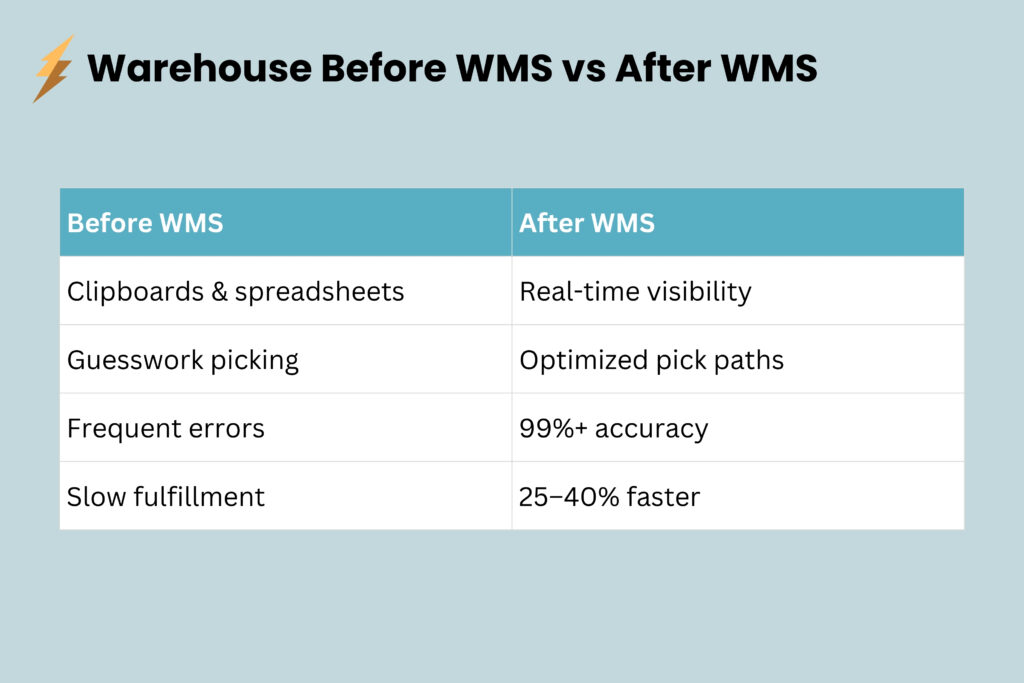

The Evolution from Paper to Intelligent Systems

Warehouses used to run on clipboards, spreadsheets, and institutional knowledge locked in workers’ heads. Early WMS software just digitized those paper processes-basically turning your clipboard into a screen. But warehouse management system software has gotten smarter. Today’s systems use algorithms to optimize pick paths in real time, predict inventory needs, and adapt to changing conditions throughout the day. The best 3PL warehouse management platforms can even automate receiving decisions, suggest better slotting strategies, and flag potential stockouts before they happen. You’re not just replacing paper anymore-you’re adding intelligence that paper could never provide.

Not all WMS software is built the same, and the feature lists vendors hand you can read like grocery store receipts. What you need to know is which warehouse management features actually move the needle on the metrics you’re accountable for.

Core WMS Features That Drive Results

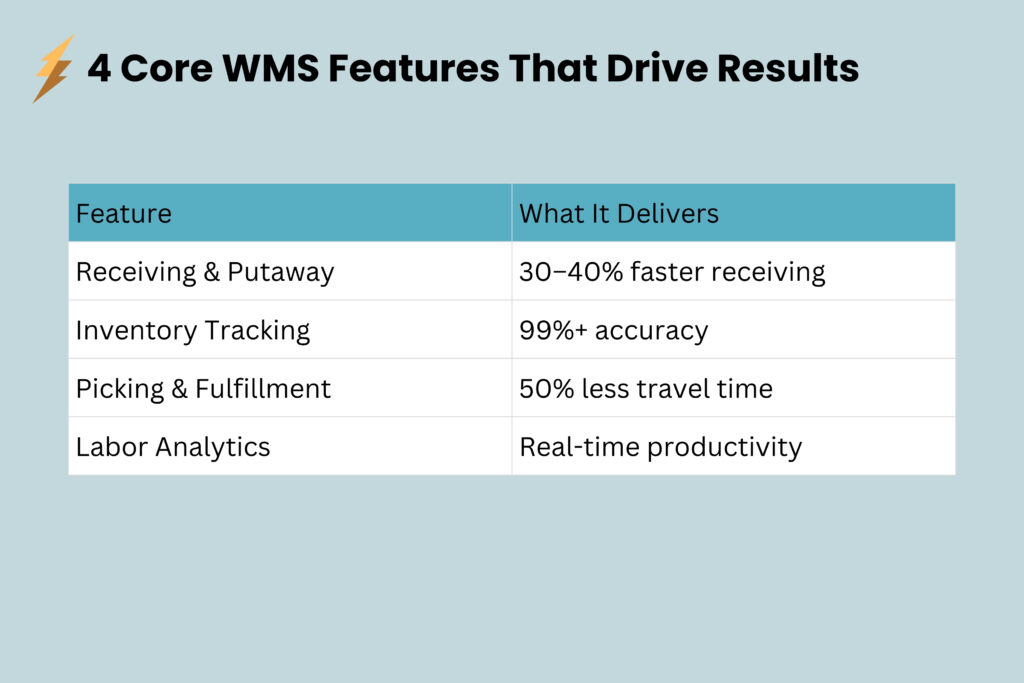

Receiving and Putaway Optimization

Your receiving process sets the tone for everything downstream. Modern warehouse management systems use directed putaway logic that tells workers exactly where to place incoming inventory based on velocity, size, and available space. Fast-moving items land in prime picking zones, while slower SKUs head to overflow locations. The system generates putaway tasks in real time, eliminating the guesswork and cutting receiving times by 30-40% compared to manual methods.

Inventory Tracking and Location Management

Real-time inventory visibility isn’t optional anymore. WMS software tracks every unit down to the bin level using barcode scanning or RFID technology. You’ll know exactly what’s in stock, where it’s sitting, and when it’s due to expire. This granular location management prevents the “we have it somewhere” problem and keeps inventory accuracy rates above 99%, which is critical for 3PL warehouse management when you’re handling multiple clients under one roof.

Order Picking and Fulfillment

Picking drives your labor costs more than any other warehouse activity. A solid warehouse management system optimizes pick paths, batches orders intelligently, and supports multiple picking strategies like wave picking, zone picking, or pick-and-pass. The software calculates the most efficient route through your facility and can reduce travel time by up to 50%.

Labor Management and Analytics

You can’t improve what you don’t measure. Cloud warehouse management systems track individual and team productivity in real time, showing you pick rates, accuracy scores, and where bottlenecks form during peak periods. These analytics help you staff appropriately, identify training opportunities, and set realistic performance standards based on actual data rather than guesswork.

You’re not shopping for software because you love reading vendor brochures. You need to know if the investment actually moves your numbers, and whether the disruption of implementing a warehouse management system is worth the payoff.

Benefits of Implementing a Warehouse Management System

Measurable Operational Improvements

Modern WMS software typically pushes inventory accuracy above 99%, which means you’re not discovering stockouts when customers are already waiting. Order picking accuracy jumps to similar levels because workers follow system-directed workflows instead of relying on memory or paper lists. You’ll see fulfillment speed increase by 25-40% as the system optimizes pick paths and eliminates the wandering that eats up hours every day.

Real-time visibility becomes standard instead of aspirational. You know exactly what inventory you have, where it sits, and when it’ll ship without running a physical count or digging through spreadsheets.

Cost Reduction and Financial Impact

Labor represents your biggest controllable expense, and a warehouse management system cuts the hours needed per order by directing workers efficiently and reducing error-correction time. You’ll reclaim 15-30% of your warehouse space through optimized slotting and storage density improvements, which delays or eliminates costly expansions.

Fewer picking errors mean fewer returns, replacements, and angry customer calls. Those costs add up faster than most operations managers realize.

Strategic Advantages and Scalability

Cloud warehouse management systems let you scale without infrastructure headaches. Adding a new facility or doubling order volume doesn’t require building custom workarounds or hiring three more people to manage spreadsheets. Your WMS grows with you, supporting multi-warehouse operations and complex fulfillment strategies that would break manual systems.

Shopping for warehouse management system software means wading through vendor demos that all promise the same thing. The real question isn’t which system has the longest feature list, but which one fits how you actually operate and where you’re headed in the next three years.

Choosing the Right Warehouse Management System

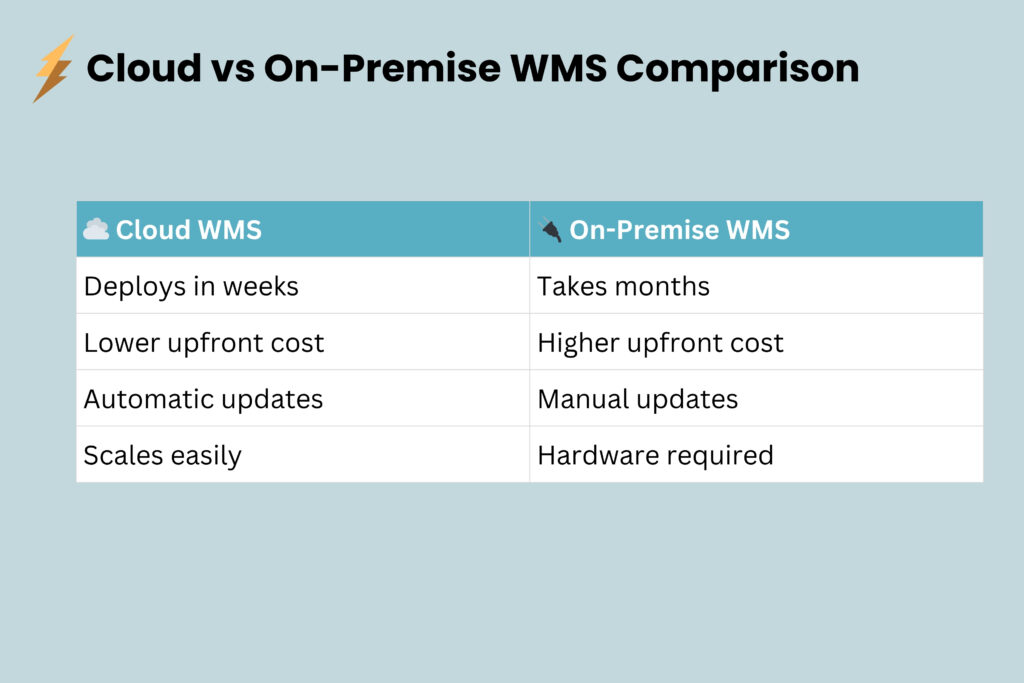

Deployment Models: Cloud vs On-Premise

Cloud warehouse management systems get you live faster, typically in weeks instead of months, and you’re paying a monthly subscription instead of dropping six figures upfront. Your vendor handles updates, security patches, and infrastructure headaches while you focus on running your warehouse.

On-premise WMS software gives you more control over customization and data, but you’re paying for servers, IT support, and every upgrade. Most growing operations default to cloud these days because the total cost of ownership is lower and scaling doesn’t require hardware purchases.

Key Selection Criteria

Start with integration capabilities because your WMS software needs to talk to your order management system, ERP, and shipping carriers without constant middleware patches. Ask vendors for customer references who run similar operations to yours, not just their biggest logos.

Look at the reporting dashboard during demos and ask yourself if you can actually understand what you’re seeing without a training manual. User adoption makes or breaks implementations, so if your team can’t figure out the interface quickly, you’ll waste months on training instead of seeing results.

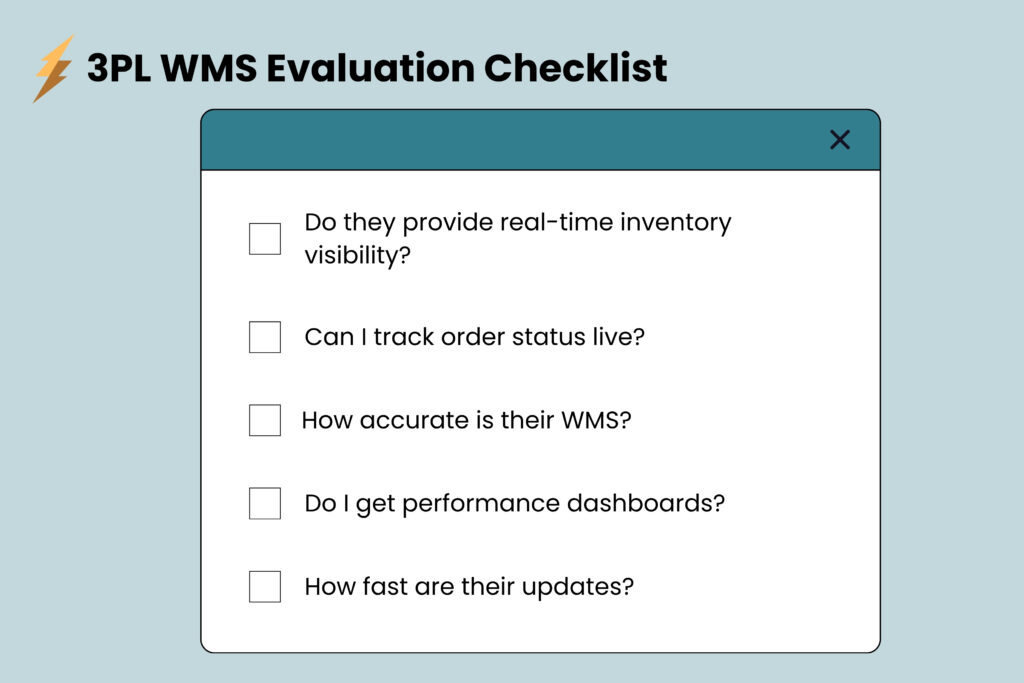

For Brands Evaluating 3PL Partners

When you’re outsourcing fulfillment, your 3PL’s warehouse management system becomes your system by extension. Ask potential 3PL warehouse management partners what visibility you’ll get into inventory levels, order status, and performance metrics. If they can’t give you real-time data access or their reporting feels like pulling teeth, that’s your signal to keep looking.

FAQ

⌛ How long does it take to implement a warehouse management system?

Cloud-based WMS implementations typically take weeks rather than months, while on-premise systems can require significantly longer timelines. The actual duration depends on your warehouse complexity, how much data you’re migrating, and whether you need custom integrations with existing systems. Most modern cloud warehouse management systems are designed for faster deployment so you can start seeing results quickly.

💭 What's the difference between cloud and on-premise warehouse management systems?

Cloud WMS runs on vendor-hosted servers with monthly subscription pricing and faster implementation, while on-premise systems require upfront capital investment and your own IT infrastructure. Cloud systems handle updates and security automatically, which means less technical overhead for your team. On-premise gives you more control over customization but requires dedicated IT resources to maintain.

💯 Can a WMS actually improve inventory accuracy to 99%?

Yes, modern warehouse management systems routinely push inventory accuracy above 99% by tracking every unit down to the bin level using barcode scanning or RFID technology. The system directs workers through specific workflows that eliminate guesswork and manual errors. Real-time tracking means you always know what’s in stock and exactly where it sits, which is particularly critical for 3PL operations managing multiple clients.

📉 How does a WMS reduce labor costs?

A WMS calculates optimal pick paths that can cut travel time by up to 50%, reducing the hours needed per order by 15-30%. The system directs workers efficiently and minimizes time spent on error corrections, returns, and hunting for misplaced inventory. Labor management analytics also show you exactly where bottlenecks form and help you staff appropriately based on real data.

🤔 Do I need a WMS if my warehouse is still growing?

Growing warehouses benefit most from implementing a WMS before operational chaos forces the issue. If inventory counts don’t match your shelves, orders ship late or wrong, or you’re relying on spreadsheets for visibility, you’re already at the point where a WMS pays for itself. Cloud warehouse management systems scale with you, so adding volume or facilities doesn’t require rebuilding your entire operation from scratch.

The Bottom Line

A warehouse management system stops being optional when inventory errors, late shipments, and labor costs start threatening your margins. The right WMS software gives you real-time visibility, cuts picking errors to near zero, and reclaims 15-30% of your warehouse space through smarter operations. This isn’t about digitizing paper processes-it’s about adding intelligence that makes your warehouse run faster with fewer people.

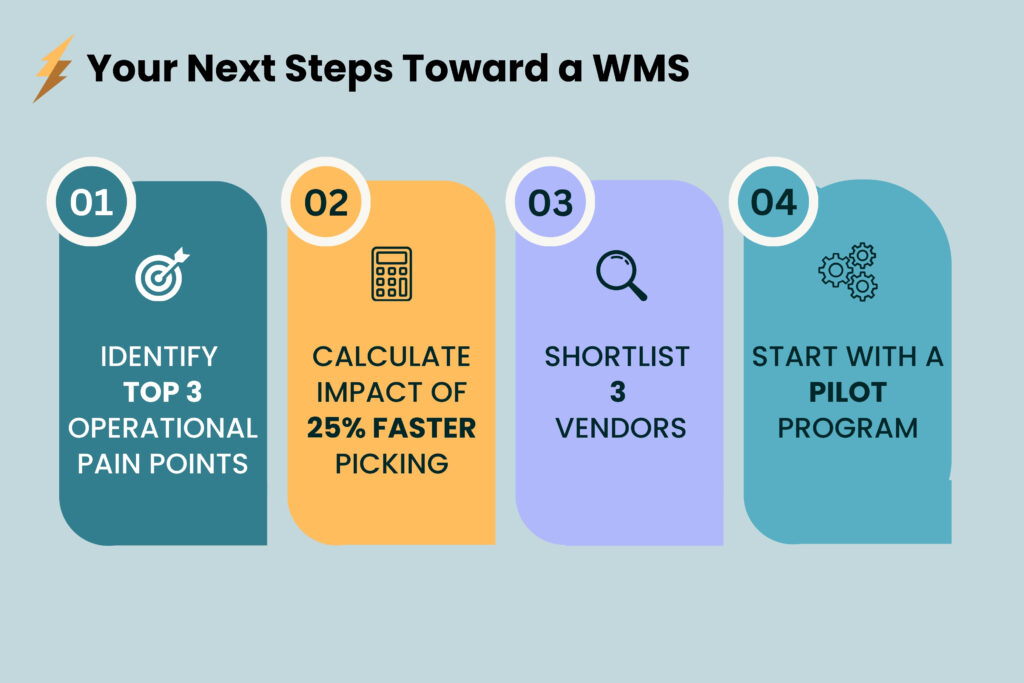

Here’s what you should do next:

- Document your three biggest operational pain points right now-whether that’s inventory accuracy, fulfillment speed, or labor costs-and use those as your evaluation criteria

- Calculate what a 25% reduction in picking time and 99% inventory accuracy would mean for your bottom line this year

- Talk to three vendors, but focus your questions on implementation timelines, integration requirements, and what happens when things break

- Start with a pilot in one zone or product category rather than attempting a full warehouse cutover on day one

Your warehouse won’t fix itself, and spreadsheets won’t scale past where you are today. Pick a system that matches your current operation but can handle double your volume, then commit to the implementation before your competition does.

WMS Glossary Terms

-

WMS = Warehouse Management System

-

OMS = Order Management System

-

TMS = Transportation Management System

-

Directed Putaway = Rules-based storage placement

-

Slotting = Optimizing SKU locations